Guide clamps are essential tools used to hold materials in place during fabrication‚ ensuring precision and stability. They are widely used in woodworking‚ metalworking‚ and 3D printing to maintain alignment and prevent movement during processing‚ enhancing accuracy and efficiency in various industrial applications. Their versatility makes them indispensable for both professionals and hobbyists‚ supporting consistent and high-quality results in manufacturing and crafting projects.

1.1 What is a Guide Clamp?

A guide clamp is a specialized tool designed to securely hold materials in place during manufacturing or crafting processes. Its primary function is to ensure proper alignment and stability‚ preventing movement that could lead to inaccuracies. Widely used in industries like woodworking‚ metalworking‚ and 3D printing‚ guide clamps are essential for maintaining precision. They are often integrated into jigs and fixtures to enhance the consistency of production. By providing a firm grip on workpieces‚ guide clamps help reduce errors and improve overall efficiency. Their versatility allows them to be adapted to various tasks‚ making them indispensable for both professionals and hobbyists. Whether for cutting‚ drilling‚ or assembling‚ guide clamps play a crucial role in achieving high-quality results.

1.2 Importance of Guide Clamps in Various Industries

Guide clamps are integral to various industries‚ playing a critical role in ensuring precision‚ stability‚ and efficiency. In woodworking‚ they prevent materials from warping or shifting during cutting and assembly‚ ensuring accurate results. In metalworking‚ they maintain alignment during machining‚ reducing errors and improving safety. The automotive industry relies on guide clamps for assembling and aligning components‚ while 3D printing uses them to stabilize print beds‚ preventing print failures. Across industries‚ guide clamps minimize production errors‚ enhance workflow‚ and contribute to the overall quality of finished products. Their versatility and reliability make them indispensable tools‚ enabling consistent and high-performance outcomes in both small-scale and large industrial applications.

1.3 Brief History of Guide Clamps

The origins of guide clamps trace back to early woodworking and metalworking practices‚ where the need for precise alignment and stabilization of materials became evident. Initially‚ simple clamps made of wood and metal were used‚ evolving over time with advancements in manufacturing techniques. The Industrial Revolution brought significant improvements‚ introducing adjustable clamps that could handle various materials and thicknesses. Modern guide clamps emerged in the 20th century‚ incorporating durable materials like aluminum and steel‚ and featuring adjustable arms for versatility. Today‚ guide clamps are indispensable in industries ranging from woodworking to 3D printing‚ reflecting a long history of innovation aimed at enhancing precision and efficiency in fabrication processes.

Design and Construction of Guide Clamps

Guide clamps are engineered with precision‚ combining durable materials and robust mechanisms to ensure secure material alignment. Their design focuses on versatility and reliability across various applications.

2.1 Key Components of a Guide Clamp

A guide clamp typically consists of a base‚ clamping jaw‚ adjustment mechanism‚ and locking system. The base provides stability‚ while the clamping jaw securely holds the material in place. The adjustment mechanism allows precise positioning‚ ensuring proper alignment. The locking system‚ often a screw or lever‚ secures the clamp tightly. Some models include guide rails for smoother operation and enhanced accuracy. These components work together to ensure reliable performance across various applications‚ from woodworking to metalworking‚ making guide clamps indispensable for maintaining precision and stability during fabrication processes. Each part is designed to withstand heavy use‚ ensuring durability and consistency in industrial and crafting projects.

2.2 Materials Used in Guide Clamp Manufacturing

Guide clamps are manufactured using durable materials to ensure longevity and performance. Common materials include stainless steel for corrosion resistance‚ aluminum for lightweight applications‚ and high-carbon steel for strength. Plastics and polymers are also used for certain components‚ offering flexibility and resistance to wear. Rubber or silicone pads are often incorporated to prevent surface damage during clamping. In industrial settings‚ titanium and carbon fiber may be used for high-strength‚ lightweight solutions. The choice of material depends on the application‚ ensuring the clamp can withstand the demands of its environment. These materials are selected for their ability to provide consistent clamping force‚ durability‚ and resistance to environmental factors‚ making guide clamps reliable tools across various industries.

2.3 Custom and Standard Guide Clamps

Guide clamps are available in both standard and custom designs‚ catering to different needs. Standard guide clamps are pre-manufactured to fit common applications‚ offering cost-effectiveness and quick availability. They are ideal for typical projects where specific dimensions and features are not required. Custom guide clamps‚ however‚ are tailored to meet unique specifications‚ such as unusual shapes‚ sizes‚ or materials; These are often used in specialized industries or for complex projects requiring precise fitment. While standard clamps are more affordable and readily accessible‚ custom clamps provide solutions for unique challenges. The choice between the two depends on the project’s requirements‚ budget‚ and the level of customization needed. Both options ensure reliability and efficiency‚ making them essential tools in various manufacturing processes.

Applications of Guide Clamps

Guide clamps are versatile tools used across various industries to ensure precision and stability. They are applied in woodworking‚ metalworking‚ and 3D printing to maintain material alignment‚ enhancing efficiency and product quality.

3.1 Guide Clamps in Woodworking

Guide clamps are indispensable in woodworking‚ ensuring precise alignment and stability during cutting‚ drilling‚ and assembly. They prevent wood from shifting‚ reducing errors and improving safety. F-style clamps are particularly popular‚ offering durability and adjustability. By securing materials firmly‚ guide clamps enable accurate cuts and joints‚ essential for professional and DIY projects. Their versatility makes them a must-have tool for woodworking‚ enhancing efficiency and craftsmanship in creating high-quality furniture and decorative pieces.

3.2 Guide Clamps in Metalworking

In metalworking‚ guide clamps play a critical role in ensuring precision and stability during fabrication processes. They are used to securely hold metal components in place‚ preventing movement or distortion during cutting‚ welding‚ or machining. Guide clamps are particularly useful in maintaining alignment for complex assemblies‚ where even slight misalignment can lead to costly errors. Their robust design makes them ideal for withstanding the rigors of metalworking‚ including high temperatures and heavy forces. By providing a reliable clamping solution‚ guide clamps enhance productivity and accuracy‚ making them an essential tool in modern metal fabrication. Their versatility allows them to be adapted to various metalworking tasks‚ ensuring consistent and high-quality results.

3.3 Guide Clamps in 3D Printing

Guide clamps are increasingly utilized in 3D printing to enhance precision and stability during the printing process. They are particularly useful for maintaining the alignment of print beds and ensuring proper adhesion of the first layer‚ which is critical for successful prints. In multi-material or dual extruder setups‚ guide clamps help keep components securely in place‚ minimizing the risk of misalignment. They are also used to hold custom builds or modifications‚ such as adding secondary extruders or filaments. Guide clamps prevent warping and shifting of prints‚ especially on large-scale or complex designs. Their adaptability makes them a valuable tool for both hobbyists and professionals in 3D printing‚ ensuring consistent and high-quality outcomes. By providing a reliable clamping solution‚ guide clamps contribute to the advancement of 3D printing technology.

3.4 Other Industrial Applications

Guide clamps are versatile tools with applications beyond woodworking‚ metalworking‚ and 3D printing. In the automotive industry‚ they are used to align vehicle frames and panels during assembly‚ ensuring precise fits and reducing rework. In plastic injection molding‚ guide clamps help maintain mold alignment‚ crucial for producing consistent parts. They are also employed in CNC machining to securely hold materials in place‚ preventing movement during high-precision cuts. Additionally‚ guide clamps are used in aerospace for aligning components and in construction for securing heavy machinery parts. Their ability to provide stable and repeatable positioning makes them indispensable across various sectors‚ enhancing productivity and accuracy. Whether in manufacturing‚ assembly‚ or specialized industries‚ guide clamps play a key role in maintaining operational efficiency and quality standards.

Installation and Setup of Guide Clamps

Installing guide clamps requires precise alignment and secure fastening. Use appropriate tools like wrenches or Allen keys‚ ensuring proper tightening to avoid misalignment. Always follow manufacturer guidelines for optimal setup and performance.

4.1 Tools Required for Installation

To install guide clamps effectively‚ you’ll need a set of essential tools. A wrench or socket set is necessary for tightening bolts and securing the clamp in place. Screwdrivers‚ both flathead and Phillips‚ are required for adjusting the clamp’s alignment and setting its position. A measuring tape or caliper ensures accurate placement and alignment with the workpiece. Lubrication‚ such as grease or oil‚ may be needed to maintain smooth operation. Additionally‚ clamps or vises can help stabilize the workpiece during installation; For more complex setups‚ a level tool ensures proper alignment. Always consult the manufacturer’s guidelines for specific tool recommendations. Having these tools ready will streamline the installation process and ensure a secure‚ precise setup.

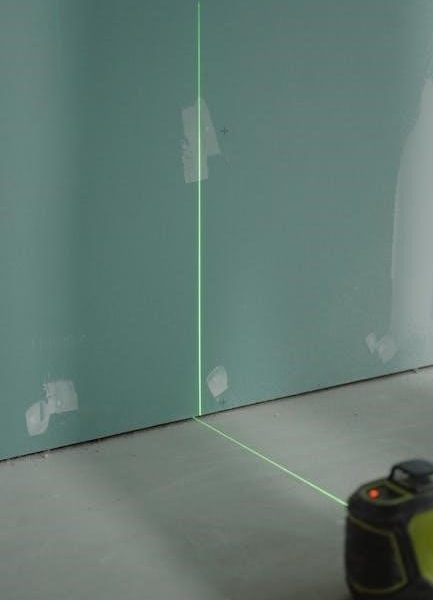

4.2 Step-by-Step Installation Guide

Installing guide clamps requires careful planning and execution. Start by preparing the workpiece and ensuring it is clean and dry. Position the clamp at the desired location‚ aligning it with the material’s edges or reference points. Tighten the clamp gradually‚ checking its stability as you go. Use the adjustment screws to fine-tune the alignment‚ ensuring it is square and even. Once properly aligned‚ secure the clamp using the recommended fasteners. Double-check the clamp’s position and tighten all bolts firmly. Finally‚ test the clamp by applying gentle pressure to the workpiece to ensure it holds securely. Follow the manufacturer’s instructions for specific torque values and installation techniques. Proper installation ensures optimal performance and safety. Always verify alignment before proceeding with your project.

4.3 Common Mistakes to Avoid

When installing guide clamps‚ several common mistakes can compromise their performance. Over-tightening is a frequent error‚ as it may damage the material or the clamp itself. Another mistake is failing to properly align the clamp with the workpiece‚ leading to inaccurate results. Many users also neglect to clean the contact surfaces before installation‚ which can reduce the clamp’s grip and stability. Additionally‚ using the wrong clamp size for the material thickness is a common oversight‚ resulting in poor hold or difficulty in securing the material. Lastly‚ ignoring the manufacturer’s torque specifications can lead to unsafe conditions and reduced clamp effectiveness. Always ensure the clamp is evenly tightened and the workpiece is properly prepared to avoid these issues and achieve reliable results.

Maintenance and Care of Guide Clamps

Regular cleaning and lubrication of guide clamps ensure optimal performance. Remove dirt and debris to prevent interference with alignment. Store clamps in a dry‚ protected environment to avoid rust. Always inspect for wear and tear before use to maintain reliability and safety.

5.1 Cleaning and Lubrication

Cleaning and lubrication are critical for maintaining the functionality of guide clamps. Regularly remove dirt‚ dust‚ and debris using compressed air or a soft-bristled brush to ensure smooth operation; For tougher residue‚ dampen a cloth with mild detergent and wipe down surfaces‚ avoiding harsh chemicals that might damage materials. After cleaning‚ apply a high-quality lubricant to moving parts to reduce friction and prevent corrosion. Ensure all surfaces are dry before reassembling or storing the clamps. Neglecting lubrication can lead to wear and tear‚ while excessive lubricant may attract more dust. Schedule cleaning and lubrication every 3-6 months‚ depending on usage‚ to extend the lifespan of your guide clamps and maintain optimal performance in industrial applications.

5.2 Routine Maintenance Schedule

A routine maintenance schedule is essential to ensure guide clamps function optimally and last longer. Inspect the clamps every 3-6 months‚ depending on usage‚ to identify wear and tear. Check for loose screws‚ misalignment‚ or damaged components and tighten or replace them as needed. Lubricate moving parts regularly to prevent rust and ensure smooth operation. Additionally‚ verify the alignment accuracy of the clamps to maintain precision in your work. Neglecting maintenance can lead to reduced performance and increased wear. Always refer to the manufacturer’s guidelines for specific recommendations tailored to your guide clamp model. By following a consistent maintenance routine‚ you can prevent potential issues and ensure reliable operation over time.

5.3 Troubleshooting Common Issues

Guide clamps can occasionally encounter issues that affect their performance. One common problem is misalignment‚ which can occur due to improper installation or wear over time. To fix this‚ recalibrate the clamp by adjusting its base or replacing worn-out parts. Another issue is clamping force inconsistency‚ often caused by dirt or debris buildup. Cleaning the clamp’s surfaces and ensuring proper lubrication can resolve this. If the clamp fails to hold material securely‚ check for loose screws or damaged pads and tighten or replace them as needed. Regular inspection and maintenance can help prevent these issues. Always refer to the manufacturer’s troubleshooting guide for specific solutions tailored to your guide clamp model. Addressing problems promptly ensures optimal functionality and extends the lifespan of your clamps.

Safety Considerations with Guide Clamps

Ensure proper handling and secure placement to avoid accidents. Tighten firmly but avoid over-tightening. Use protective gear and ensure compatibility with materials to prevent damage or injury.

6.1 General Safety Precautions

When working with guide clamps‚ it is crucial to follow safety guidelines to prevent accidents and ensure safe operation. Always wear protective gear‚ such as gloves and safety glasses‚ to protect yourself from potential hazards. Ensure the workpiece is securely fastened to prevent sudden movement‚ which could cause injury. Avoid over-tightening clamps‚ as this may damage the material or the clamp itself. Keep loose clothing and long hair tied back to avoid entanglement. Never leave clamps unattended while in use‚ and ensure the workspace is clear of obstacles to maintain a safe working environment. Regularly inspect clamps for wear and tear‚ and replace any damaged components promptly. Follow the manufacturer’s instructions for proper usage and load capacity to avoid mishaps. Proper safety practices will help prevent accidents and ensure efficient‚ trouble-free operations.

6.2 Hazards Associated with Improper Use

Improper use of guide clamps can lead to significant hazards‚ including equipment damage‚ injury‚ and reduced productivity. Over-tightening or misaligning clamps may result in material breakage or deformation‚ compromising the integrity of the workpiece. Loose clamps can cause sudden movement of materials during processing‚ potentially leading to accidents. Additionally‚ using clamps beyond their load capacity or on inappropriate surfaces can result in clamp failure‚ posing a risk of flying debris. Incorrect installation or failure to secure clamps properly may also lead to operational instability‚ increasing the likelihood of accidents. Furthermore‚ neglecting regular maintenance or ignoring worn-out components can exacerbate these risks‚ making proper usage and adherence to guidelines critical for safe and effective operation.

6.3 Best Practices for Safe Operation

Adhering to best practices ensures the safe and effective use of guide clamps. Always follow the manufacturer’s instructions and conduct regular inspections to identify wear or damage. Properly train personnel on clamp installation‚ adjustment‚ and operation to minimize risks. Use clamps suitable for the material and load to prevent overload or slippage. Ensure clamps are securely fastened and aligned before starting work. Avoid over-tightening‚ as this can damage equipment or materials. Monitor clamps during operation and adjust as needed. Store clamps in a clean‚ dry environment to prevent corrosion. Regular lubrication of moving parts and timely replacement of worn components are essential for optimal performance. Additionally‚ wear protective gear‚ such as gloves and safety glasses‚ when handling clamps and materials. Stay alert and follow safety protocols to prevent accidents and ensure smooth workflow. Proper adherence to these practices enhances safety and operational efficiency.

Future Trends in Guide Clamp Technology

Future trends in guide clamp technology include automation‚ smart systems‚ and integration with emerging technologies like IoT‚ offering enhanced precision‚ efficiency‚ and adaptability in industrial applications.

7.1 Smart Guide Clamps and Automation

Smart guide clamps are revolutionizing industries by integrating automation and intelligent technologies. These clamps use sensors‚ IoT connectivity‚ and AI to optimize clamping forces and positioning‚ ensuring precision in real-time. Automation enables hands-free operation‚ reducing human error and increasing productivity. Smart clamps can adapt to varying materials and workflows‚ making them ideal for advanced manufacturing. Their integration with CNC machines and robotic systems streamlines production processes‚ allowing for seamless communication and synchronization. Additionally‚ smart guide clamps can collect data for performance analytics‚ enabling predictive maintenance and process optimization. This fusion of hardware and software is driving the future of manufacturing‚ making operations faster‚ smarter‚ and more efficient.

- Enhanced precision through real-time adjustments.

- Automation reduces manual intervention and errors.

- Integration with smart factories and Industry 4.0.

7.2 Modular Guide Clamp Systems

Modular guide clamp systems offer flexibility and adaptability in various industrial applications. These systems consist of interlocking components that can be customized to meet specific project requirements. Users can combine different clamp sizes‚ bases‚ and accessories to create tailored setups‚ reducing the need for multiple tools. Modular systems are particularly useful in workshops‚ factories‚ and DIY projects‚ where versatility is key. They are cost-effective‚ as they eliminate the need for purchasing separate clamps for different tasks. Additionally‚ modular guide clamps save space and promote organization‚ making them ideal for both small-scale and large-scale manufacturing environments. Their interchangeable design ensures compatibility with a wide range of materials and workflows.

- Customizable for specific tasks and materials.

- Cost-effective and space-saving.

- Ideal for workshops‚ factories‚ and DIY projects.

7.3 Integration with Emerging Technologies

The integration of guide clamps with emerging technologies‚ such as smart manufacturing and IoT‚ is revolutionizing industrial workflows. Modern guide clamps are now being equipped with sensors and automation capabilities‚ enabling real-time monitoring and precise control. This integration allows for seamless communication between clamps and other machinery‚ optimizing production processes; Additionally‚ advancements in robotics and AI are enabling guide clamps to adapt automatically to different materials and tasks‚ reducing human intervention. These innovations enhance accuracy‚ efficiency‚ and safety in manufacturing environments. The fusion of guide clamps with cutting-edge technologies is setting new standards for precision and adaptability in various industries‚ ensuring they remain essential tools in the era of Industry 4.0.

- Smart sensors for real-time monitoring.

- Automation and AI-driven adjustments.

- Seamless integration with robotic systems.

Guide clamps have proven to be versatile tools‚ enhancing precision and efficiency across industries. Their adaptability to emerging technologies ensures continued relevance in modern manufacturing and crafting.

8.1 Summary of Key Points

Guide clamps are versatile tools essential for maintaining precision and stability in various industrial and crafting applications. Their design ensures proper alignment and prevents material movement during processing‚ enhancing accuracy and efficiency. Widely used in woodworking‚ metalworking‚ and 3D printing‚ guide clamps are valued for their durability and adaptability. Constructed from robust materials‚ they offer long-term reliability and can be customized to meet specific requirements. Regular maintenance‚ including cleaning and lubrication‚ is crucial for optimal performance. Safety precautions must be followed to avoid hazards associated with improper use. As technology advances‚ guide clamps are evolving to integrate with smart systems and modular designs‚ ensuring their continued relevance in modern manufacturing. Understanding their importance‚ applications‚ and proper care is key to maximizing their utility in any project.

8.2 Final Thoughts on Guide Clamps

Guide clamps are indispensable tools that enhance precision‚ stability‚ and efficiency in various industries and projects. Their versatility‚ ease of use‚ and reliability make them a cornerstone in woodworking‚ metalworking‚ and 3D printing. By ensuring proper alignment and preventing material movement‚ guide clamps significantly improve the quality of finished products. Their durability and adaptability to different tasks underscore their value in both professional and hobbyist settings. As technology advances‚ guide clamps are likely to become even more sophisticated‚ offering enhanced functionality and integration with smart systems. For anyone seeking to elevate their craftsmanship and productivity‚ investing in high-quality guide clamps is a worthwhile decision that promises long-term benefits and consistent results.

8.3 Recommendations for Future Use

For optimal use of guide clamps in the future‚ it is recommended to invest in high-quality‚ durable models that align with specific project requirements. Regular maintenance‚ such as lubrication and inspection‚ will ensure longevity and performance. Users should explore customization options to tailor clamps to their unique needs‚ enhancing functionality and efficiency. Staying updated on technological advancements‚ such as smart clamps and automation‚ can further improve workflows. Additionally‚ investing in training or tutorials can help users maximize the benefits of guide clamps. Exploring modular systems and interchangeable parts can also provide flexibility for diverse projects. By adopting these practices‚ users can ensure they are leveraging guide clamps to their full potential‚ achieving precise and consistent results across various applications.