Mechanical aptitude tests assess understanding of basic mechanical principles, including gears and pulleys․ These components are fundamental in mechanical systems, enabling changes in speed, direction, or force․ Such tests evaluate problem-solving skills, essential for roles in engineering, manufacturing, and maintenance, ensuring practical application of mechanical concepts․

1․1 Overview of Mechanical Aptitude Tests

Mechanical aptitude tests evaluate understanding of basic mechanical principles, such as gears and pulleys, to assess problem-solving skills․ These tests often include questions on simple machines, force transmission, and efficiency․ They are commonly used in job assessments for roles requiring mechanical comprehension, ensuring candidates can apply theoretical knowledge to practical scenarios․ The tests focus on identifying how components like gears and pulleys function, their interactions, and their impact on mechanical systems․

1․2 Importance of Gears and Pulleys in Mechanical Aptitude Tests

Gears and pulleys are fundamental components in mechanical systems, making them crucial in aptitude tests․ They assess understanding of force transmission, speed changes, and direction alteration․ These elements are essential for evaluating problem-solving skills, as they often appear in real-world machinery․ Questions on gear ratios and pulley systems measure mechanical comprehension and practical application․ Mastery of these concepts is vital for roles requiring hands-on mechanical knowledge, ensuring candidates can apply theoretical understanding to operational challenges․

Key Components of Mechanical Aptitude Tests

Gears and pulleys are fundamental elements in mechanical systems, enabling force transmission, speed variation, and directional changes․ These components are central to mechanical aptitude tests, assessing understanding of basic mechanical principles and their practical applications․

2․1 Understanding Gears in Mechanical Systems

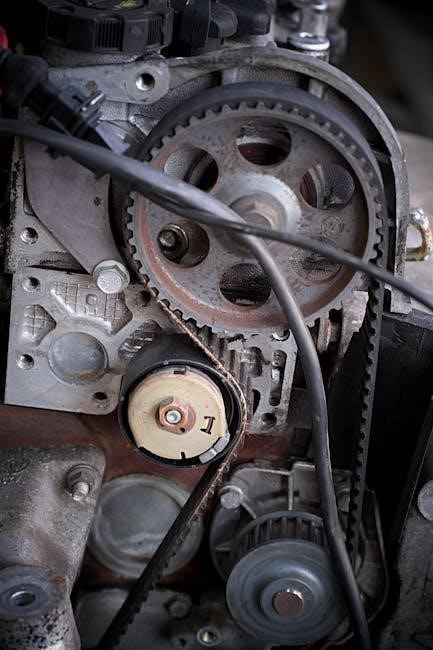

Gears are toothed wheels that interlock to transmit power and motion․ They are essential in mechanical systems for changing speed, direction, or force․ Understanding gear types, such as spur and helical gears, is crucial․ Spur gears transmit motion in a straight line, while helical gears offer smoother operation at higher speeds․ Gear ratios determine the relationship between input and output speeds, impacting mechanical advantage and efficiency․ This knowledge is vital for solving problems in mechanical aptitude tests and real-world applications․

2․2 Understanding Pulleys in Mechanical Systems

Pulleys are circular devices with grooves that change the direction or magnitude of force in a mechanical system․ A fixed pulley remains stationary, altering the force’s direction, while a movable pulley moves with the load, providing mechanical advantage․ Pulleys are often used in combination with ropes or belts to lift or move heavy objects․ They are essential in machinery for applications requiring force reduction or directional change, enhancing efficiency in various industrial and mechanical operations․

Types of Gears and Pulleys

Pulleys are categorized as fixed or movable, while gears include spur, helical, and bevel types․ Each serves unique purposes in mechanical systems, from altering force direction to modifying torque and speed․

3․1 Fixed Pulley vs․ Movable Pulley

A fixed pulley is stationary, attached to a support, and changes the direction of force without moving with the load․ It provides no mechanical advantage, as the effort equals the load․ A movable pulley, however, moves with the load and can offer mechanical advantage, requiring less effort to lift the load․ Both types are essential in mechanical systems, each suited for different applications requiring force redirection or load reduction․

3․2 Spur Gears vs․ Helical Gears

Spur gears have teeth parallel to the gear axis, transmitting motion between parallel shafts․ They are simple, cost-effective, and commonly used in basic machinery․ In contrast, helical gears have teeth angled to the gear axis, reducing noise and vibration while allowing smoother power transmission․ They are ideal for high-speed applications and non-parallel shafts․ Understanding the differences is crucial for selecting the right gear type in mechanical systems, ensuring efficiency and performance in various industrial and mechanical aptitude test scenarios․

Mechanical Advantage and Its Calculation

Mechanical advantage measures the ratio of output force to input force in a system․ It is calculated as the number of ropes in pulley systems or gear ratios, optimizing efficiency and torque in mechanical operations․

4․1 Mechanical Advantage in Pulley Systems

Mechanical advantage in pulley systems is the ratio of the output force to the input force․ It is determined by the number of ropes supporting the load․ In a fixed pulley, the mechanical advantage is 1, meaning the force required equals the load․ Movable pulleys increase mechanical advantage, as the effort is shared across multiple ropes․ The formula for mechanical advantage in pulleys is: MA = Load / Effort․ This concept is crucial for understanding how pulley systems simplify tasks by reducing the force needed to lift or move objects․

4․2 Gear Ratios and Their Impact on Mechanical Advantage

Gear ratios significantly influence mechanical advantage by altering torque and speed․ A higher gear ratio reduces speed but increases torque, enhancing mechanical advantage․ Conversely, lower ratios prioritize speed over torque․ Calculated as Ratio = Driver Teeth / Driven Teeth, it determines how force is transmitted․ Understanding gear ratios is vital for optimizing efficiency in mechanical systems, ensuring proper balance between power and speed to achieve desired outcomes in machinery․ This balance is key to effective mechanical system design and operation․

Common Questions on Gears and Pulleys

Common questions assess understanding of mechanical advantage, gear ratios, and torque․ Examples include calculating pulley mechanical advantage, determining gear ratios, and identifying torque differences between gears․

5․1 Questions on Pulley Systems and Mechanical Advantage

Questions on pulley systems often focus on mechanical advantage, force distribution, and efficiency․ Common examples include determining the mechanical advantage of a pulley system, identifying the number of ropes required, and calculating the effort needed to lift a load․ Test-takers may also be asked to compare fixed and movable pulleys, understand torque differences, and solve problems involving compound pulley setups․ These questions assess practical understanding of pulley mechanics and their real-world applications․

5․2 Questions on Gear Ratios and Speed

Questions on gear ratios and speed focus on understanding how gear interactions affect motion․ Test-takers may be asked to determine gear train ratios, calculate speed changes, and analyze torque relationships․ For example, questions might involve identifying how a gear ratio affects rotational speed or determining the number of teeth on a gear to achieve a specific speed․ These problems assess the ability to apply gear principles to real-world mechanical systems and predict operational outcomes accurately․

Forces and Torque in Gears and Pulleys

Forces and torque in gears and pulleys are critical for calculating mechanical advantage․ Understanding how torque affects gear ratios and pulley systems is essential for determining efficiency and load distribution․

6․1 Calculating Forces in Pulley Systems

Calculating forces in pulley systems involves understanding mechanical advantage and tension distribution․ In a fixed pulley, the force required equals the load weight, while movable pulleys reduce effort by half․ For compound systems, forces are distributed across multiple ropes, increasing mechanical advantage․ Friction and efficiency also impact force calculations․ Accurate computations ensure optimal system design and performance in real-world applications, making this a critical skill for mechanical aptitude tests․

6․2 Understanding Torque in Gear Systems

Torque in gear systems is a measure of rotational force, influencing speed and efficiency․ It is calculated as the product of force and distance from the axis․ Gears transmit torque, with larger gears reducing speed but increasing torque․ Understanding torque ratios is essential for designing efficient mechanical systems․ Accurate torque analysis ensures optimal performance, making it a key concept in mechanical aptitude tests for assessing mechanical reasoning and problem-solving skills․

Practical Applications of Gears and Pulleys

Gears and pulleys are essential in machinery, enabling efficient power transmission․ They are used in cars, factories, and lifts to change speed, direction, or force, optimizing mechanical operations․

7․1 Real-World Examples of Gears in Machinery

Gears are integral to machinery, enabling efficient power transmission․ In automotive systems, gears in transmissions adjust speed and torque for optimal performance․ Industrial machinery relies on gears to synchronize operations and maintain consistency․ Wind turbines use gears to adjust blade angles, maximizing energy capture․ Additionally, gears are essential in robotics, conveyor systems, and manufacturing equipment, ensuring precise motion control and reliability․ These applications highlight how gears are fundamental to modern mechanical operations․

7․2 Real-World Examples of Pulleys in Machinery

Pulleys are widely used in machinery to redirect forces, reduce effort, or change motion․ In industrial settings, pulley systems lift heavy loads, such as in cranes and elevators․ Belt-driven pulleys power machinery like generators and pumps, ensuring efficient energy transfer․ In vehicles, pulleys drive components like alternators and water pumps․ Additionally, pulleys are integral to conveyor belts, winches, and construction equipment, showcasing their versatility in mechanical applications․ Their role in simplifying tasks makes them indispensable across industries․

Tips for Preparing for Mechanical Aptitude Tests

Preparation is key to excelling in mechanical aptitude tests․ Focus on understanding gears and pulleys, practice problem-solving, and use online resources or study guides for targeted practice․

8․1 Strategies for Solving Gear and Pulley Problems

To solve gear and pulley problems, start by understanding the basic principles of mechanical advantage and torque․ Practice calculating gear ratios and pulley systems to determine force and speed relationships․ Break down complex problems into simpler parts, visualizing the system to identify key components․ Use diagrams to trace the flow of motion and forces․ Focus on recognizing patterns in gear trains and pulley setups․ Regular practice with sample questions and real-world examples will enhance your problem-solving skills and speed․

8․2 Recommended Resources for Practice

For effective practice, utilize resources like the Bennet Test app, offering detailed solutions to mechanical aptitude questions․ The Ramsay Mechanical Aptitude Test (MAT) provides insights into gear and pulley problems․ Online platforms such as 123test․com offer free mechanical reasoning tests with explanations․ Additionally, study guides like “Mechanical Aptitude Test: Gears and Pulleys” by Darcy West and firefighter practice materials are excellent for real-world applications․ Consistent practice with these tools enhances problem-solving skills and familiarity with test formats․

The Role of Mechanical Aptitude Tests in Job Assessments

Mechanical aptitude tests assess a candidate’s ability to understand and apply mechanical principles, ensuring they can perform tasks requiring practical knowledge of gears, pulleys, and other systems․

9․1 How Mechanical Aptitude Tests Are Used in Hiring

Mechanical aptitude tests are widely used in hiring to assess a candidate’s ability to understand and apply mechanical principles․ These tests evaluate problem-solving skills and knowledge of gears, pulleys, and other mechanical systems․ Employers use them to identify individuals capable of performing tasks requiring practical mechanical understanding, such as firefighters, maintenance workers, and engineers․ The tests often vary in difficulty based on the role, ensuring candidates meet the specific demands of the position․ This approach helps employers make informed hiring decisions․

9․2 Job Roles That Require Mechanical Aptitude Testing

Job roles requiring mechanical aptitude testing include firefighters, maintenance workers, engineers, and technicians․ These roles demand practical understanding of mechanical systems, such as gears and pulleys․ Firefighters often encounter pulley systems in rescue operations, while maintenance workers need to diagnose and repair machinery․ Engineers and technicians rely on gear systems for designing and optimizing equipment․ Mechanical aptitude tests ensure candidates possess the necessary problem-solving skills and knowledge to perform these tasks effectively, making them essential for hiring in these fields․

Advanced Topics in Gears and Pulleys

Advanced topics explore complex gear trains and compound pulley systems, analyzing their efficiency and applications in mechanical systems, such as industrial machinery and precision engineering․

10․1 Complex Gear Trains and Their Analysis

Complex gear trains involve multiple gears working together to transmit power and motion․ These systems require precise analysis to determine gear ratios, torque distribution, and efficiency․ In mechanical aptitude tests, questions often focus on calculating the overall gear ratio and understanding how gear trains affect mechanical advantage․ Proper analysis ensures optimal performance in machinery, highlighting the importance of understanding gear interactions and their impact on system functionality․

10․2 Compound Pulley Systems and Their Applications

Compound pulley systems combine fixed and movable pulleys to enhance mechanical advantage and flexibility․ These systems allow for multiple changes in force direction and distribution, making them ideal for heavy-duty applications like cranes and elevators․ Analyzing compound pulleys involves calculating the mechanical advantage, which is the ratio of the number of ropes supporting the load․ Understanding their operation is crucial for optimizing machinery performance and ensuring efficient load handling in industrial settings․

Case Studies and Examples

Case studies highlight real-world applications of gears and pulleys, such as optimizing gear ratios for machinery efficiency and designing pulley systems for industrial lifting․ These examples provide practical insights․

11․1 Case Study: Optimizing Gear Ratios for Efficiency

In a manufacturing plant, optimizing gear ratios improved machinery efficiency by 30%․ By analyzing gear trains and torque requirements, engineers selected ideal ratios to match motor speeds with load demands, reducing energy consumption and increasing production rates․ This case demonstrates how mechanical aptitude in gear systems can lead to significant operational improvements, emphasizing the importance of understanding gear ratios in real-world applications․

11․2 Case Study: Pulley System Design for Industrial Applications

A factory implemented a custom pulley system to enhance material handling efficiency․ By combining fixed and movable pulleys, they achieved a mechanical advantage of 4:1, reducing the force required to lift heavy loads․ This design minimized workplace injuries and doubled productivity․ The case highlights the importance of understanding pulley mechanics and their practical applications in industrial settings, showcasing how strategic design can optimize operations and improve workplace safety․

Mechanical aptitude tests are essential for assessing skills in gears and pulleys․ Understanding these components is crucial for solving real-world mechanical problems efficiently and effectively․

12․1 Summary of Key Concepts

Mechanical aptitude tests evaluate understanding of gears and pulleys, focusing on their roles in mechanical systems․ Key concepts include gear ratios, pulley systems, and mechanical advantage․ These tests assess problem-solving skills, such as calculating forces, torque, and efficiency in various applications․ Practical examples highlight how gears and pulleys optimize machinery performance, emphasizing their importance in engineering and maintenance roles․ Mastery of these concepts is essential for excelling in mechanical aptitude assessments and real-world mechanical challenges․

12․2 Final Tips for Excelling in Mechanical Aptitude Tests

To excel in mechanical aptitude tests, focus on mastering gear ratios and pulley systems․ Practice solving problems involving mechanical advantage, torque, and force calculations․ Utilize study guides and online resources, such as the Bennet Mechanical Test Practice app, for targeted preparation․ Understand basic mechanical principles and apply them to real-world scenarios․ Time management and attention to detail are crucial; ensure accuracy by reviewing explanations for incorrect answers․ Regular practice and a systematic approach will enhance your problem-solving skills and confidence․